Operational Tests Phase II

Objective

The pilot project is intended to provide the technical basis so that migration of a DAC can be implemented Europe-wide. In the process, the aim of phase II was the implementation of coupling and driving trials in scenarios which equate to regular operation of rail freight transport (RFT). For this purpose, more than 25 shunting yards were used to test the functions of the DACs. This included trials on the (automated or manual) hump, in the gravity yard, in the shunting yard with retarder mode and in the port terminal with railway sidings or customer railways sidings. Furthermore, the operational processes were assessed and optimisation opportunities which would be favourable to the introduction of the DACs into regular operation, were discussed. In the same way, the operation of the DACs was assessed and requirements for optimisation for this purpose were identified.

The investigations focussed on both the mechanical behaviour of the coupling designs and the electrical characteristics of the electric couplings for power and data transmission.

Tests Cases

The DAC tests are carried out in actual operating scenarios. The following key test areas and corresponding test scenarios were defined:

Marshalling on level ground

The DAC tests are carried out in actual operating scenarios. The following key test areas and corresponding test scenarios were defined:

Wagon run-off with hump, non-automated, in retarder mode

Wagons are pushed over the hump by a marshalling or remote control locomotive and roll off under gravitational force. Bad runners or wrongly-routed wagons are pushed back into the sorting sliding and the procedure repeated.

Wagon run-off with hump, fully automated (run-off control computer and conveyor system)

Wagons are pushed over the hump and braked using a computer-controlled braking system according to running characteristics and weight.

Wagon run-off in gravity yard, non-automated, in retarder mode

Due to the gradient of the station, the wagons roll into the sorting sidings.

Wagon run-off in gravity yard, fully automated (with run-off control computer)

Due to the gradient of the station the wagons roll into the sorting sidings and are braked using a computer-controlled braking system according to running characteristics and weight.

Current and data measurements

An overview of the current and data measurements in phase II is shown below.

| Energy supply | Data transmission |

|---|---|

| Verification of reliability of the electric coupling and availability of energy supply, including the buffer battery, during field testing. | Continuous measurement of the selected communication system based on a concept for operation on the demonstrator train. Adaptation of test concepts from phase I for the phase II tests with optimisations for the selected communication system. |

| Continuous measurementsContinuous recording of relevant variables (supply voltage, power demand) and the integrity of the power system (insulation monitoring). | Generation of data loads for measurement of data processing capacity, measurement of performance in terms of latency. |

| Recurring testsMonitoring of correct function of components in the supply circuit, measurement of transfer and insulation resistances, determining the charging/discharging characteristics of the buffer batteries. | Determining the reliability/availability of the communication system by measuring the packet error rate. |

| Measuring the initialisation time of the communication system in practise. |

MEASURING TECHNOLOGY

In phase I, the focus was on detailed measurements of the constantly identical wagon configuration and the comparison of the various DAC designs. Electricity for charging the systems or for operating the hardware was generally available.

With the beginning of phase II, the trials were no longer carried out on a specific test site but rather at facilities all over Europe. The journeys to these destinations were also used systematically in order to gain knowledge of the performance of the train during the journey. For this purpose, the measuring system was designed with two modes. For train journeys, all the wagons were either connected via the DACs or by cable. The electricity supplied via the DACs was thus used to operate the measuring technology. All the measured data was transmitted directly to the measuring wagon in this case. In this mode, it was not possible to disconnect the coupling points readily because of the cables.

As a result, these connections were not in place for trials in shunting operation and the wagons had to be capable of carrying out measurements independently. For this purpose, the individual wagons were equipped with their own batteries and their own data capture devices.

There were a total of six different equipment categories which are listed in the following table.

Indication of the categories for wagons equipped with wagons, including installed sensors

| Category | Capable of carrying out measurements independently | Sensors | Carriage types |

|---|---|---|---|

A | ✔️ |

| S wagonH wagon |

B | ✔️ |

| H wagon |

C | x |

| Z wagonE wagon |

D | x |

| Z wagon |

E | x | (Carriage is used as a signal amplifier only) | S wagon |

F | x | Uas wagonF Wagon |

Test locations

The tests are performed at operating locations and on routes with specific characteristics.

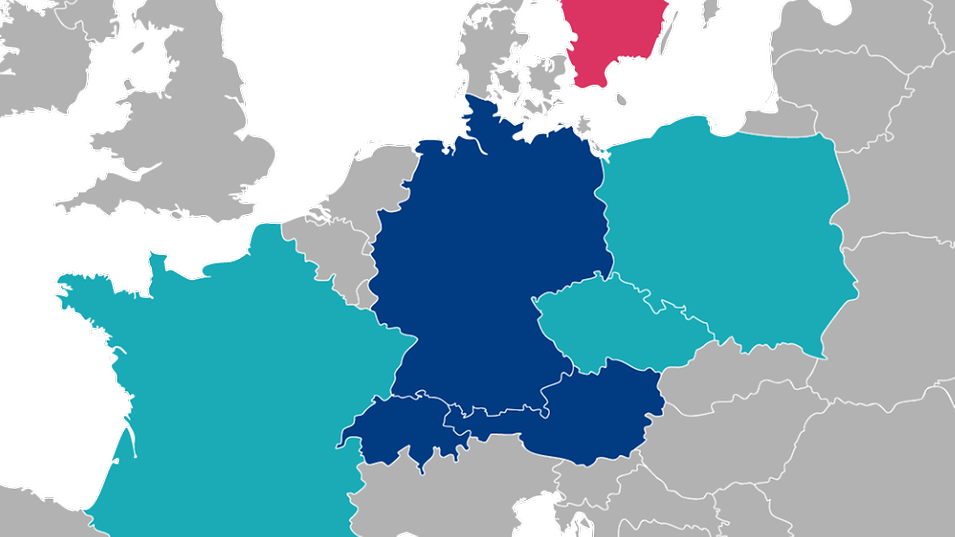

The marshalling yards and an example network of the routes to be travelled during field testing until March 2022 are shown in Figure 1. Location which are shown in light grey are optional and will be approached if the time and route map allows.

Legend:dark blue = consortium partners (D, CH, A); turquoise = test countries (F, PL, CZ); pink = cooperation partners (S); marker = test locations (see table)

Location

Test sites DE | Test sites Switzerland | Test sites Austria | Test sites Poland | Test sites Czech Republic | Test sites France | Test sites Luxembourg |

|---|---|---|---|---|---|---|

Mannheim/Ludwigshafen | Basel | Rankweil | PoznańFranowo | Ostrava | Straßburg | Bettemburg |

München Nord | Zürich | Selzthal | Wapienno | Brno-Maloměřice | ||

Ingolstadt | Gotthard | Niklasdorf | DąbrowaGórnicza | Plzeň | ||

Nürnberg | Wien | ZabrzegCzarnolesie | ||||

Kassel/Bebra | Zebrzydowice | |||||

Bremerhaven | ||||||

BremenSebaldsbrück |

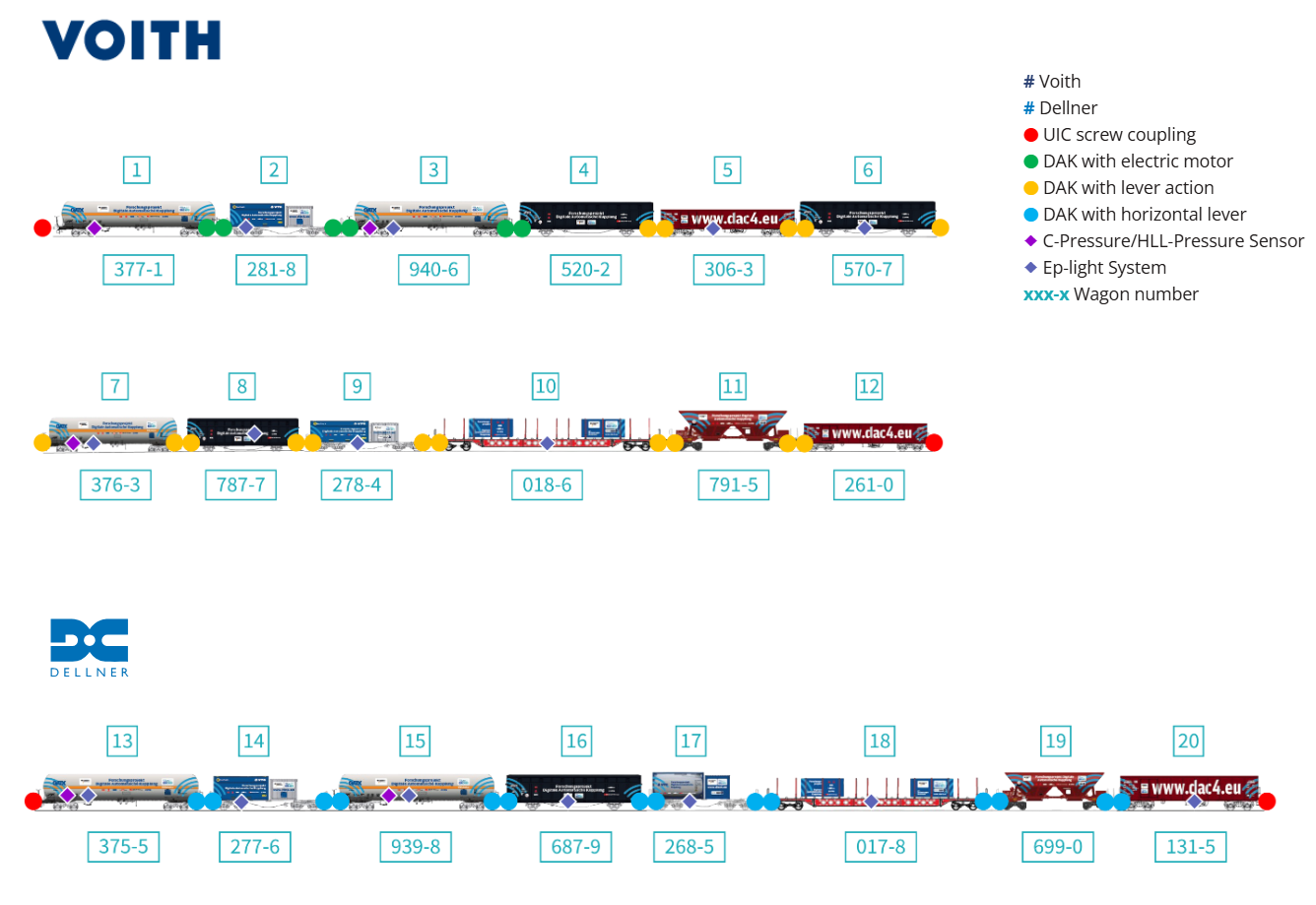

Demonstration Train in Phase II

For phase II, the DAC4EU demonstrator train was gradually extended to 20 wagons with the selected Scharfenberg or latch-type coupling design. In the process, three new wagon types were added:

Within the scope of the trials, the train integrity check was used to monitor the communication systems. At all times, it was known that the train was complete, meaning that this information had to be supplied to the systems without interruption.

Automation Components in the Demonstrator Train

A further focus of the work during phase II is the selection of suitable automation components in order to verify the functionality of the power and data supply in the demonstrator train.

The following functions or automation components are to be set up in phase II: