Testing of the operational DAC for RFT Phase III+IV

Objective

Phases III and IV were implemented as part of the first project extension from January 2023 to June 2024. The focus was on the further technical development and practical testing of the digital automatic coupling (DAC).

In phase III, open questions from the previous project phases were specifically investigated. These included noise development during coupling, the behaviour of the coupler on static and dynamic rolling stock weighbridges and its reaction to longitudinal compressive forces. At the same time, new components such as revised spring assemblies, variants of the electric coupler and electrically actuated uncoupling systems were tested in detail.

Phase IV comprised subsequent operational tests under real conditions - in shunting operations, on the hump and on ferries. The aim was to validate the interaction of the further developed systems in practical use and to assess their reliability in everyday operations.

Test cases

As part of phases III and IV, tests were also carried out both during train journeys and in shunting operations. With the help of the findings from all previous tests, the number of necessary tests could be significantly reduced so that fewer test days were required in total to test the manufacturers' products and gain specific findings.

In addition to the general driving and manoeuvring tests, known from the tests in phases I and II, special tests were carried out. These resulted from uncertainties or challenges that were identified during the previous trials.

Special tests

- Corrosive environments: Here, the wagons were parked in the direct vicinity of a salt place of loading for several weeks and repeatedly examined. No abnormalities were detected.

- Rolling stock weighbridge: With the support of BASF and Qlar (formerly Schenck Process), tests were carried out on static and dynamic rolling stock weighbridges. It was shown that there are deviations in the weighing due to the DAC, but that these can be compensated for by correction factors.

- Ferry ramp: A special case of shunting handling is operation on train ferries. On the one hand, the connection between the ferry and the landside often results in steep gradients with sometimes angular transitions. On the other hand, there is only limited space in the ferry, so that otherwise unusual track geometries are often used. It has been shown that no operational problems have occurred. The only problem today is that the wagons are secured by a buffer stop, which would have to be converted for the DAC.

- Shunting coupler: One challenge for changing the coupling system from side buffer to centre buffer coupler is the large number of shunting devices, some of which are very old, but all of which are designed to transmit tractive forces in the centre and compressive forces via the side buffers.As part of the trials, a solution from Voith was investigated that can be retrofitted to the screw coupling hook with little effort. Both raising and uncoupling are done pneumatically. The tests showed that the operation is robust and reliable compared to existing solutions such as the RK900 shunting coupler, but that the transmission of the compressive forces is a particular problem. In the RK900, this takes place via the side buffers, which are no longer present in the DAC. This means that the compressive forces are limited by the load capacity of the train set or locomotive.

Road tests

During the driving tests as part of the trials, the 400V AC (alternating voltage) supply to the carriages was examined for the first time. The reliable transmission of energy via the DAC was further confirmed. As part of the evaluation of the driving tests, an automated procedure was developed to analyse train journeys and present them in a standardised and clear manner. This made it possible to quickly assess the loads on the couplings and identify different types of train journeys. Based on this data, load collectives can be determined or derived in future. These collectives can then be used as a reference for the qualification of the components and as input values for the definition of representative test procedures. A presentation of this evaluation can be found in Appendix 2 of the interim reports Phase III and IV.

Shunting tests

Phase III and IV also showed that two challenges remain for the DAC systems in shunting:

- Incomplete uncoupling: When a coupling is operated, the couplings separate, whereby one or both coupling locks do not engage in the uncoupled position, but fall back into the coupled position.

- Manual uncoupling: There are two main requirements for manual uncoupling:

- Low operating force

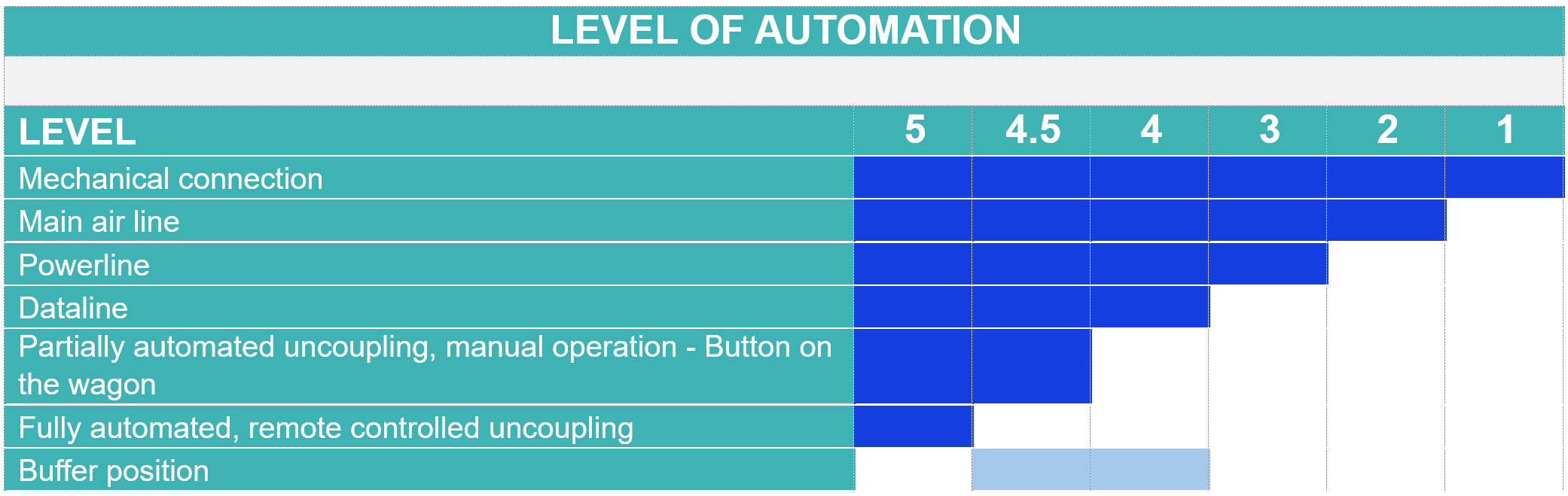

- Integration into hump operationIn hump yard operation, wagons roll into the sorting sidings at speeds of 4-5 km/h (standard systems) or up to 15 km/h (high-performance systems) after being uncoupled. Different national regulations increase the requirements for manual operation.

This results in centralised operating requirements:

- Uncoupling must be possible during movement.

- A buffer position must be adjustable to prevent unintentional coupling when pushing off.

- It must be possible to operate the DAC from both long sides of the wagon (as only one side is usually accessible on a hill).

- Wagons travelling over the hill must arrive in the ready-to-couple position.

- The subsequent remote control of the DAC must be compatible with manual uncoupling.

Power and data

The electrical system test focussed on the new 400 V AC power supply system and the electric coupling. The connection via the new pin/socket contacts worked reliably, as did the data communication via SPE and Powerline+. Challenges arose in the monitoring of insulation faults and the sensitivity of the couplings to moisture. In addition, the capacitive coupling in the AC system can influence the protection in the event of a fault. These findings are directly incorporated into further development and risk assessment.

Detailed tests

- Noise measurements: The tests of the new couplings showed that they are louder than screw couplings. Measurements of the noise emissions of Voith and Dellner systems enabled an objective comparison.

- Comparative measurements of electric couplings: The electric couplings (e-couplings) had to be robust both mechanically and in terms of data transmission. In addition, their height is above the previous buffer edge, which can potentially lead to collisions in wagons with end flaps.Both systems passed the tests without any major damage. There were differences when uncoupling: Voith remained open in the event of incomplete uncoupling, while Knorr-Bremse frequently exhibited incomplete uncoupling.

- Flow measurements: Pneumatic brake systems are used almost exclusively in freight transport. In the DAC prototypes tested, a valve opens the connection when coupling and closes it when uncoupling, which influences the braking behaviour. Tests have shown that the valve type, hose length and number of components determine the release times, with optimised DAC valves reacting faster than current screw couplings. These findings are being incorporated into the further development of the systems.

- Sliding tests: In sliding tests with DAC trolleys, longitudinal compressive forces of up to 550 kN were achieved without any critical vehicle reactions. Bogie wagons proved to be more stable than two-axle wagons. Older DAC versions showed poorer stabilisation behaviour, which explains the lower bearable longitudinal compressive force. The wheel/rail contact forces are a reliable indicator of the load-bearing capacity of the wagons, while the lifting of individual wheels is less meaningful.

Test locations

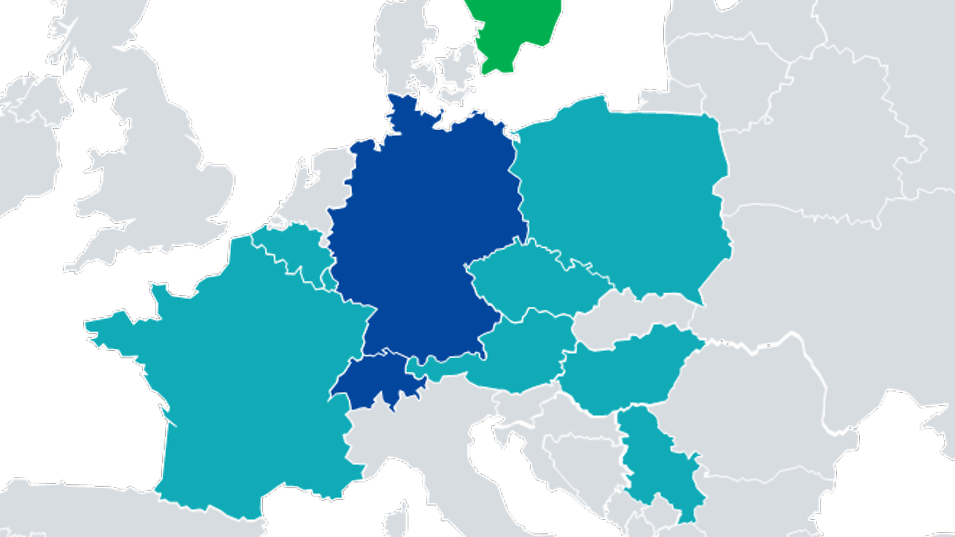

The tests were carried out at operating sites and on routes with specific characteristics.

Figure 1 shows the marshalling yards that were used in the course of the operational trials until June 2024.

Legend:dark blue = consortium partner (D, CH); turquoise = test countries (A, F, PL, CZ, HU, RS, BE ); green = cooperation partner (S); marker = test locations (see table)

Germany | Switzerland | Austria | Poland | Czech Republic | France | Luxembourg | Hungary | Serbia | Belgium |

|---|---|---|---|---|---|---|---|---|---|

Mannheim/Ludwigshafen | Basel | Rankweil | PoznańFranowo | Ostrava | Strasbourg | Bettemburg | Budapest | Belgrade | Brussels |

Munich North | Zurich | Selzthal | Wapienno | Brno-Maloměřice | |||||

Ingolstadt | Gotthard | Niklasdorf | DąbrowaGórnicza | Plzeň | |||||

Nuremberg | Vienna | ZabrzegCzarnolesie | |||||||

Kassel/Bebra | Villach | Zebrzydowice | |||||||

Bremerhaven | |||||||||

BremenSebaldsbrück |

Figure 1 - Degree of automation

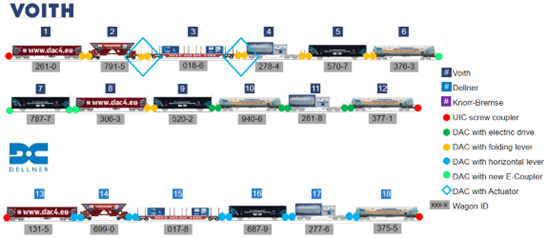

For Phase III and IV, the DAC4EU demonstrator train was upgraded to 21 wagons with the selected Scharfenberg or latch type coupling design. Three new wagon types were added:

As part of the trials, train integrity control was used to monitor the communication systems. It was known at all times that the train was complete, so this information had to be delivered without interruption by the systems.

Coupling manufacturers

Voith

As uncoupling from the carriage side was initially not possible, three additional uncoupling mechanisms were added. Uncoupling while the wagon is moving is carried out exclusively electrically via an externally mounted actuators. In addition, the buffer position was retrofitted, the front plate of the coupler head was adapted for winter conditions, four new coupler heads and weight-optimised coupler rods were installed and the electric coupling was optimised for better centring, a flatter design and a 400 V AC connection.

Dellner

Following the push-on tests in phase I, the UIC stabilising joint was adapted to reduce lateral forces under longitudinal pressure. In addition, the Generation 3 spring assembly was optimised and a buffer position retrofitted. Phase III saw the installation of the further improved Generation 3.5, and a manual uncoupling mechanism with buffer position was also trialled for a time.

Knorr Bremse

The DAC from the manufacturer Knorr-Bremse was included in the test operation from December 2023. No further optimisations were subsequently made to the coupling. Only a hydraulically reinforced, manual uncoupling mechanism was temporarily fitted and tested.